Micro G PIC Ultimate

To obtain a singleor

copy write to the PCB ad.noctis@gmail.com

while stocks last

Tutorial

available on the Internet for use and operation of the development:

-

Part one (only in. Doc). How to create the project, obtain the file. Hex and

test the operation of the simulator

-

Part

second Tutorial "link the card to the PC via

232

-

Part Three of the

Tutorial "use of 'I / O digital versatile Micro-GT PIC IDE

With I.D.E. is

mean Developed Integrated Environment then Cn development system

projects microcontrollers, the PIC series, capable of integrating a high

number of peripheral devices. The electronic card contains: A programmer

compatible serial 8076, housing for a 2x16 character LCD display,

the space for a graphic display Glcd (graphic liquid crystal display) 128

x 64 points, an H bridge from 8 amps continuous, a dual full bridge for the L298

drive a stepper motor bipolar or two DC motors to

up to 2 amps, a 7-segment LED display 4 digits in controllable

multiplexer providing BCD code to the integration of decoding, 16 buttons

jumper selectable pull up or pull down in groups of 4, 24 outputs

maximum indicated by digital LEDs, Streep direct access to I / O

PIC, 8 analog inputs with simulated trimmer. A large number of dip

selectable switches and jumpers allow you to change the functionality of

various points of connection to the PIC. It can easily connect a high

number of actuators. The system is designed to program the PIC

40, 28, 18-pin dual in line, and in other ways ICSP (in circuit serial

programming) and you can move the clock signal, or even

select an appropriate setting of quartz with a jumper with

jumpers.

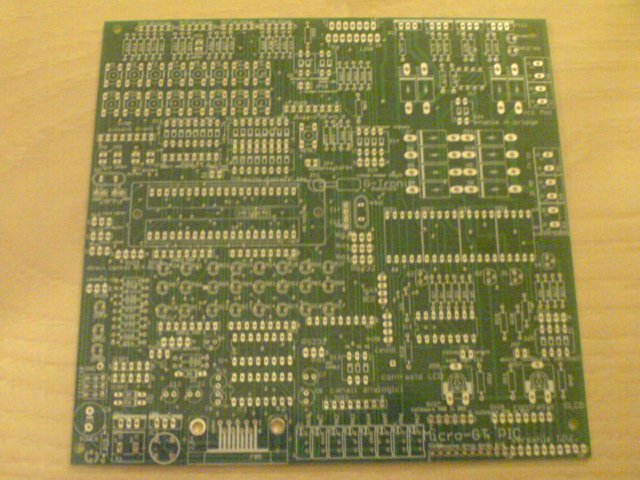

The support developed PCB

FR4 technology (dual layer) so far 164 mm x 156mm.

After

launch the automatic routing of the PCB looks like in the picture

below, we note that a single missing link fortunately

marginal interest between LED 11 and the jumper SV13. We will attempt to resolve

but the problem manually in case of failure must be carried by running

this link via a bridge wire wrap. The result is still very

satisfactory given the complexity of the circuit and the compact size. The

circuit is now optimized by increasing the slopes where possible. will indeed

a must to maximize the thicknesses of the zones used to control

power, ie insofar as it relates to the bridge chip and H

multiwatt L298 to drive a bipolar stepper motor.

Download the layout with the routing

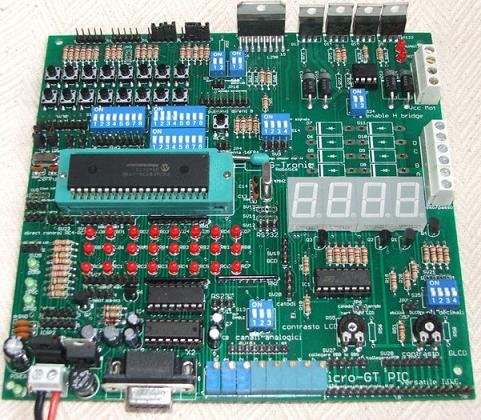

In the next

image we see a copy of the PCB made.

Files

gerber construction can be found by contacting

bonzisandy88@hotmail.com that will help make you an interpreter

ordering at a Chinese factory.

Download PDF

Schematic

Download Schematic and PCB in Eagle

Format

The underlying

picture we can see some examples of the PIC Micro-GT versatile IDE

to assembled from Internet users after you get the PCB.

Copy edited by Luca Luise, User www.grix.it. After have made this wonderful specimen, and be signed

extensive testing has offered to perform the fittings for the less

experts. To know how much it costs you a copy assembled and tested

get in touch with him ever passing through at

Email: ad.noctis@gmail.com

Copy performed by Matthew Pontarollo,

student of social and cultural center ZIP (industrial area of Padua

centrozip@libero.it) In a

editions of the basic course of programming PIC. The base is

PIC16F877A installed.

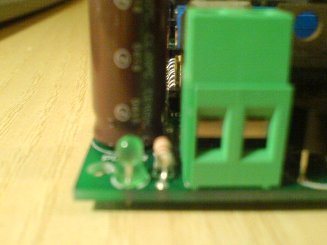

Power

Nourish

card at any voltage, either continuous or alternating current (entered a

bridge rectifier which provides a possible reversal) between

a minimum of 15V, since in some points must be 13.2 V for the flasche

PIC and must take account of the fall of drop-out of the LM stabilizers, and

a value of "ragionaevole" for the endurance of the same. It could be

example 18Va.c. or 24V dc, make sure that you alternate straightening the

multiply the nominal value of the transformer to the root of two,

or 1.4. In any case never exceed 30V, or about

value of the LM crash.

Position of the LED that indicates

power-system development Micro-GT

Communication

with the Micro Serial-GT PIC.

The serial communication

even programming with the Micro-GT is via the connector

DB9 female mounted on board. Though it would be better

connect through a real serial port of a desktop PC the link can

also occur via a USB-> RS232 interface for

with today's notebook that fitted more to this port

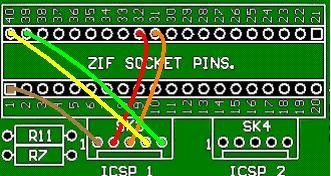

flasche the PIC using ICSP mode (in circuit serial programming)

for which you need to build in a 5-wire connector, visible in the figure, for which there will be an advantage if

respect the same colors.

ICSP connector to be built

using 5 position streep female line (if possible meet the

colors).

The correct position of

ICSP connector is shown in the next figure. you can use

either the connector ICSP1 or ICSP2 on board

tab, since these are parallel and may even

allow the programming of two chips at a time (to an external

tab). It is recommended, when they are rispettai the colors,

keep Brown on the right. The suggestion of the colors is

because it is not yet released the software

dedicated "MG-Lab, is taking care of it cu his friend Fabio,

provisionally PICPRO2009 we will use the (easily findable on the net)

that will recognize the device as "8076", or set as ICPROG

JDM reversed cable set (depends on the serial cable used).

ICSP connectors are

just above the voltage regulators.

Launching ICPROG 2009, and

entering the test section and communication, above right,

Power on, indicating it meets the correct position of

free end of the ICSP connector of the colored wires in question. maneuver

essential for programming the microcontroller. And 'good

Always keep the schemes in hand.

PICPROG 2009, during the

function tests suggests that pin to connect the wires that are colored

were used for the construction of the ICSP connector. These changes

every time you change the chip to be programmed.

ICSP settings

During the communication

and

the test using the flash

you will see PICPROG2009. Three LEDs on the side

of the ICSP connector, you'll immediately notice that the sequence

is not quite the same as

two LEDs will be reversed. Not worry about this,

remember that you are using a software

expedient, or a

provisional until it is ready

specific MG-Lab in which

the thing is already settled. However, this is only

of a signal bit in

transit (so no problem),

Signalling LED

the state of the bus for programming and communication.

The serial cable to be used

will type with two CANNON DB9 male connectors on the board side PIN

to PIN or a simple extension. Do not perform any intersection.

Wiring diagram for the cable

serial to use.

Studio Modular

project

Module

power at two levels

The module allows

power circuit with two voltage levels, a suitable

device programming PIC approximately 13.5 volts and a TTL (5V) for the

normal power of logic circuits. The voltage of 13.2 is obtained

exploiting the power generator on pin central regulators

uA78xx positive voltage range. On this leg there is a generator

4mA current that constantly pushes toward creating the standard for mass

the internal circuitry. By inserting two forward biased diodes between

center pin and the mass is added to the regulated voltage twice

Vgamma junction voltage = 0.6 volts. We get so much for the 13.2

switch in the pic programming. The PCB was added to a test point in

close dell'elettrolitico C9 which provides a ground.

discover developing their own projects how useful this point

access to the mass.

The lines that we see out of the positive

of

electrolytic C2 leads the voltage at the connector for programming

serial circuit (ICS1 and ICS2).

The voltage regulator IC3 is a

uA7805, and provides voltage to all the TTL logic circuit. The Power LED

indicates that the device is powered.

Important note: As it is

section was designed to power the circuit can be powered with

any voltage is alternating though between 9 and 36 times

volts which is the maximum limit of the regulator uA7812 we meet

first after the diodes.

The power supply section provides

about 1 amp more than enough for any state of development in

laboratory.

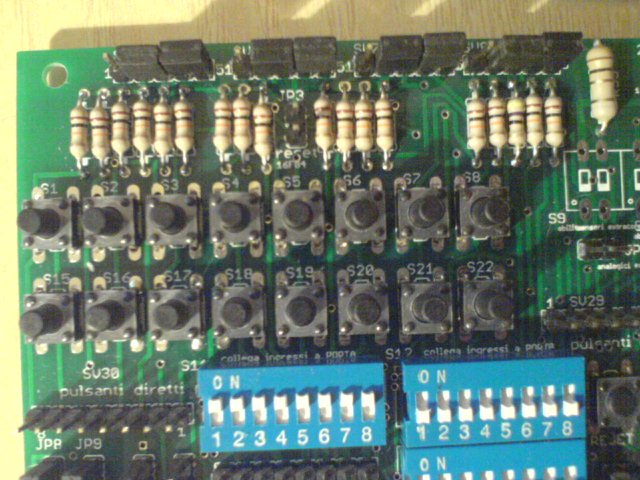

Input module

digital

The module

includes 16 push buttons on the type of mounting

PCB congener for both pressed into action to launch a 1

logical that a 0, depending on how they are configured by jumpers

related to streep SV1, SV2, SV3, SV4. Lining up all the jumpers in

buttons down the left launched a logical (in fact act as the resistance

by pull down while aligning the jumper on the right the same action

involves the launch of a logical zero (resistors act as pull up).

The inputs were dissected

in groups of 4 through steep SV1, SV2, SV3, SV4 so

to maximize the versatility of the circuit. You can simulate such a

multiples of 4 buttons is N.C. that N.A. on the machine, such as 4 N.C.

e12 NA It 's very useful function of insulation available

acting on the dip and dip S11 S12 (open switches). each button

If this continues to be nurtured and properly bound elle

TTL voltages (remains active configuration jumper on NO and NC), but now

we can bring through flat cables each of these signals at any point

or even outside of the circuit board after the board told

outside the same mass. The direct access to the buttons you can

connecting cables to the flat streep SV29 and SV30.

input section of the card

Micro-GT, are observed ipost pull-up jumpers, pull-down

Important note:

JP3 jumper must be closed when one is going to plan PIC 16F84

or a compatible 18-pin. The closure of JP3 involves connecting to ground

Pin 5 is essential for the device's power, obviously

this case the line should not be interrupted so the dip S11

must have the mandatory line 4-13 in the ON position. Required

in this case is also close the connector SV2 streep mode PULL UP

because only then will the lines to ground. Caution

polarity reversal of the feeding device even if the card

should prevent errors so gross as to be putting that Vss to Vdd

positive voltage or floating it does not result in the destruction

the CIP. S6 combines the function key to the case of MCLR or PIC16F84

microcontroller pin to pin compatible. If you wish to use this

function you need to configure the radio group S5, S6, S7, S8 must

with pull-up resistor (jumper flush right on the second group). If

you do not have this foresight program in the PIC will not start because

it receives

constantly reset signal.

Output Module

digital

The module

includes 24 digital outputs TTL logic level, which has been shown

by turning on an LED. Each of the three bytes of output can be excluded by means

1,2,3 dip switches on the S13 with the correspondence:

S13

1 -> PORT D

S13

2 -> C PORT

S13 3 ->

PORT D

It can be accessed directly

the PORT B PORT C PORT D, connected directly to SV18 streep (PORT

D), SV22 and SV23 (PORT C) and SV17 (PORT B). In the case of

direct access to the Port is not recommended to load the output

microcontroller with currents greater than a few tens of milliamps, use a

of these outputs to directly drive the coil of a relay would be really

a beginner's mistake that leads to damage to the device. Yes

also points out that for reasons of circuit simplicity has not been provided

for any input / output opto-isolation, on the other hand, this is a system

development and not a PLC although laboratory tests they can take the place.

Digital output modules, each LED is

indicated by the silkscreen on the 40 pin versionIn

yellow resistance network.

Micro-GT PIC

base model

For a user

beginner to the complete assembly of the Micro-GT could be a load

Economic a little annoying but not impossible. While waiting for the

technical expertise to use all the modules in the layout you can

restriction to assembly of the bulk of the digital I / O. The board

takes the form shown in the picture:

Features

techniques are still very respectable when compared with many products

trade. The basic model shown in the figure shows:

-

8 inputs

Digital configurable jumper in groups of 4 pull-up or pull-down.

-

Free Port Mode

which allows for example to isolate the inputs and connect them to a port

different.

-

8 digital outputs,

isolated if you want to convert the output to PORTB inputs (figure I

put a jumper but deep enough to fit the expected 2-way).

-

1 serial port

232 switch from planning to supervision arrangements

(When a software controls the I / O such as servo motors)

-

two connectors

ICSP (in circuit serial programming)

-

1 to 20 MHz quartz

-

Unit

Dual voltage power supply (running at +5 V and +13.2 V programming)

-

1 socket textool

40 pin.

-

All PIC

flaschabili executables and the full version will remain so even in

basic version (of course).

We note the

ICSP cable position, the brown is the first left, while the

Red can be disconnected because there is redundancy in the PCB for that

wire.

Fix bug MCLR for use as a base model

When you plan to

use the PIC Micro-GT are the versatile IDE 28-pin PIC or 40 as the pin

16F876 or the 16F877, or their equivalent 18 series, can be dispensed with

under special conditions of use which the board can provide when

PIC installed are of use in reality rather rare. For a more

Quick connector ICSP eseguimo na small changes that consists of:

-

Cutting the track

that connects the reset button to pin 1

-

remove the solder

a few millimeters from the track

-

bending the pins

a lower line streep two positions so that we can support from

na part of the pitch reset button and the other to the copper track

cut we found scraping the tip of the cutter.

-

Weld the streep

line in this position, insert a jumper and check the meter if

reset by pressing the buzzer sounds between pin 1 of the processor and the mass, or

the heat sink controller 7805 (note: do not try with the 7812

because it is not grounded because of the two diodes in series on the center pin).

This

simple modification is documented in the following photos:

Cutting the track.

The conductor is cut at the Vias (hole metallic) of the track

next. As we can see the solder was removed gently scraping

the track surface with a knife. This maneuver should be done to give a little

of attention even if the card is not really so delicate that it threatens

functionality.

Solder the new two-streep

positions in place so that we have made. the picture is almost

paying attention to the invisible but we can see, is parallel to

el deepswitch the left edge, as close to the base textool.

Mode implementation of the

program jumper streep sneak in line at two positions, in the photo

we see him in blue. I chose this color to highlight its presence.

In programming mode, Streep just sneak it in one of two pins of the line streep (to be

the right) and in the left hand sneak the brown wire

ICSP connector, or its pin 1. This amendment resolves any

conflict of tensions that may arise between the Implementing Rules and

the programming modeornand pic of

40 and 28 pin.

We see a turn

demo 16F877A processor, it is of the classic supercar,

remember to line up the line streep SV13 and SV14 right, this

disable quartz 4Mhz passing the bus to the pins connected to the LED, or RB5

RB4 and how we can easily see with the patterns in the hand.

download movie dl

test "supercar to PORTB" Micro-GT PIC versatile IDE

2x16 LCD Module characters

The module allows the management of a common

LCD type HD44780 compatible module, interfaced with the 4-bit method.

It will show any warning messages, or show data or

still bring the temperature detected by a sensor.

It can use two different models that differ from the display

otherwise the PIN.

The Micro-GT

versatile I.D.E. presents only the housing and PIN to link the

display using one or more flat cables, to avoid the waste of resources because

the use of the LCD is one of many possible features.

The jumper JP6

allows the backlight or power

anode-cathode of the LED integrated (PIN 15 16 anodoe cathode side display), while

streep the 3-terminal SV25 enables the connection of the first flat cable

three terminals of the LCD and is the 5 volt power supply and regulation

contrast.

With regard to

three lines needed to monitor RS / RW / E was added to the connector

SV4 three terminals. coinciding with the PIC 16F877A PORT D.

Warning: A ZIF socket

40 pin 3M is on ebay $ 0.99, equal to € 0.75, do not be fooled!

Buy on ebay even if you have to wait 10 days. Shipping included, there

costs less than 5 €.

The data lines

however, will be taken in one of the "direct access" to the port with

the freedom to decide (depending on the software developed for the PIC) the

mode 4 or 8 bits.

download the technical documentation of the display

In some models

the row of pins is shown (in parallel), even on the underside of support

Display PCB. Connecting to the one above or below it makes no difference, we use

therefore the most convenient for the wiring.

Description

The crystal display

liquid or LCD (Liquid Crystal Display English)

connected to This form has 2 lines of 16 characters

each. The LCD displays the most common commercially available, have

interface designed by Hitachi that, over time, has become a standard

Industrial also used by other manufacturers.

|

Function of various pins of the display

|

|

PIN |

Name |

Function |

|

1 |

GND |

Ground -

Pin must be connected to the negative supply. |

|

2 |

VDD |

Power Supply -

Pin to be connected to +5 V supply. |

|

3 |

Vo |

To this pin should enjoy a

variable voltage from 0 to +5 V through a trimmer to adjust the display contrast.

|

|

4 |

RS |

Register Select -

This pin is a line with which it communicates to the display

if

you are sending on the data bus (lines DB0 to DB7) a command (RS = 0)

or a data

(RS = 1). |

|

5 |

R / W |

Read, Write -

This pin is another line with which it communicates to

if you send a display means to display data (R / W = 0) or read

a display given by (R / W = 1).

|

|

6 |

E |

Enable -

This pin is a control line which can enable

display and accept data and instructions from the data bus (E = 1).

|

|

7 |

DB0 |

Data bus line 0 -

The lines to pass data between the processor and display. |

|

8 |

DB1 |

Data Bus Line 1 |

|

9 |

DB2 |

Data Bus Line 2 |

|

10 |

DB3 |

Data Bus Line 3 |

|

11 |

DB4 |

Data Bus Line 4 |

|

12 |

DB5 |

Data Bus Line 5 |

|

13 |

DB6 |

Data Bus Line 6 |

|

14 |

DB7 |

Data Bus Line 7 |

|

15 |

A |

Pin for connecting the

backlight if any.

|

|

16 |

K |

Pin for connecting the backlight if any.

|

Of the 16 pins if they use

However, only 7

RS Register select signal

E Enable signal

R / W read / wrwite selection

DB4 Data bit 4

DB5 Data bit 5

DB6 Data bit 6

DB7 Data bit 7

The data lines, RS and E

not are

with eveand a pull-down resistor to ground to force the line when

used. This was intended to maintain the

compatibility with other applications such as digital I / O pin in the same. In most cases the system will work, but if

need to add the three pulldown resistors there will be

big problems to install the outside, or edge of the display. You can

even use it in combination with SV16 line streep SV6 (see

schema) to connect the three resistors then closed to the more

near earth point.

The trimmer R55 connected to pin Vo,

through the line streep SV25 To adjust the contrast of the LCD.

Module 7-segment display, 4 digit

The module allows the management of 4

digit common cathode mode multiplexer controllable, ie it will be necessary

with the processor generating a BCD Nibble on the data bus and enabling the digit

corresponding with the launch of a Bit on the bases of transistors BC337

used in saturation, which will ban the lighting of the digit

correspondent.

particularly the seven-segment display and driver

CD4511, also highlighted the deep switch cutting and 4 for BJT

multiplex digit.

Warning: The PCB has the

sequence from left to right dis3, dis2, dis1, dis4 for reasons of convenience

routing.

download the documentation of the integrated CD4511

The IC CD4511 (equivalent to the TTL

74LS48 and LS248) takes care of the decoding of the four-bit

BCD generated with the PIC. If we use the on-board connections, which enabled

BUS using the dip switches S26 and in the case of a PIC16F877, you have the

correspondence:

A -> RB7

B -> RB6

C -> RB5

D -> RB4

As you can see from this diagram

signals are never floating even if the opening of the dip is 26

in fact brought to zero by the pulldown resistors.

Decimal points can be

separately controlled or isolated by the dip 25. If we wanted to

example, create a digital clock should only enable the dip 25

line number 2.

A good programming exercise

would be to modify the software presented on this site

on

clock 24 hours in order to do so

run on the PIC Micro-GT.

controls are: SV19 ->

direct entry of BCD data, SV20 -> control of the multiplexer

display (common cathode enables the driving transistor), SV21-> Control

4 decimal points on the display (isolated DIP 4 line S25.

Stepper motor control module

step

The module allows control

a stepper motor or two motors instead of DC with maximum current

armature games to 2 Amps continuously. E 'provided protection against

Current which must be handled in software by acquiring the signal

This analogue resistant to the two schunt. The analog signals

question shall be taken at 10 and jumpers must be reported with a

flat cable. DIP S9 disables reading.

The chip is used

known that the L298 will be powered by hand 5Volt processor and voltage

suitable for engine power in the side. The free-wheeling diodes protect the lines

extra hang him from breaking the current internal MOSFET.

The finished project

The following image we see the

PCB complete with screen prints and tracks of power reinforced. Were

enlarged mass of the tracks and all tracks affected by the passage of

current supply of engines. They are very useful to the writing that

identify the buttons and LEDs and their combined output pin of the PORT

B, C, D.

Many of the jumpers were

combined with a silkscreen that shows functionality but will always be

useful to have on hand the legend included in the instruction manual to the

correct setting. Retained in the following lines extract

the manual.

List of components

R13-R14-R15-R16 = 10k

R21-R22-R23-R24 = 10k

R25-R26-R27-R28 = 10K

R29-R30-R31-R32 = 10K

An0-AN1-AN2-AN3, AN4-AN5-AN6-AN7 = 5K ALIGNED MULTI PIN

C3-C4 = 18pF

C13-14 = 22pF

Q5 = 20Mhz

Q = 4 MHz

R12 = 10k

IC3 = 7805 - 1A

IC5 = 7812 - 1A

D2-D3 = 1N4148

C10-C11-C1 = 100nF

1 bridge 1A

R51-R52-R53-R54 = 10K

R1-R2-R3-R4-R5-R6-R7 = 220

R17-R18-R19-R20 = 220

R8-R9-R10-R11 = 1K5

IC7 = TL082

R76-75 = 10K

INSTEAD OF R78 AND R77 ZENER 2.6V CATHODE WITH THE TERMINAL INVERTING

The operational

R73-R74 = 4K7

R69-R70-R71-R72 = 1K8

Q9-Q10-Q11-Q12 = TIP122 DARLINGTON

D12-D13-D14-D15 = GI852 SCHOTTKY DIODES

D8-D9-D10-D11-D4-D5-D6-D7 = GI852 SCHOTTKY DIODES

IC6 = L298

R59-R60-R61-R62 = 1 OHM 1W

R63-R64-R65-R66-R67-R68 = 10K

IC4 = CD4049N

IC1 = CD4511

R57 = 10K LINEAR (TRIM)

R37 = 3K3

R40-R41 = 3K3

R55 = 10K LINEAR

C6-C7-C8-C5 = 1micro F electrolytic

IC2 MAX232 =

D1 = 1N4148

RN1-RN2 RN3-RESISTIVE NETWORKS = 8 + COMMON ELEMENTS 1 KOHM

TOT A STRIP OF MALE LINE

FB47-R42 = 47 OHM METAL FILM RESISTOR

R39 = FB220 = 220 OHM METAL FILM RESISTOR

JUMPER least twenty 2-POSITION

No. 17 BUTTONS REMOTE

N ° 26 LED RED 3mm

No. 4 GREEN LED 3mm

Q6 = BC547 NPN

Q7 BC557 = PNP

4 ELEMENTS 100 kOhm

R35-34 = 100 KOHM

R36 = 3K3

R33 = 10K

R38 = 100K

S12-S26-S11 DIP = 8-CHANNEL SWITCH

S25-S14 DIP = 4-CHANNEL SWITCH

S13 = 3 DIP SWITCH CHANNELS

S24-S10-S9 = 2-CHANNEL

4 7-segment display KATODO TOWN

3 16 PIN DIL

1 SOCKET 8 PIN

1 PORT DB9 FEMALE CANNON

6 SCREW TERMINAL 2 WAY

DOWNOLOAD excel file

partsearch list of components (recommended)

download the txt file list of components

Controller

supported

The following controller

have been tested and are fully supported:

- PIC10F200

- PIC12C508, PIC12CE518

- PIC12F629, PIC12F675

- PIC16F54

- PIC16F84A

- PIC16F88

- PIC16F870, PIC16F871, PIC16F872, PIC16F873A, PIC16F874

- PIC16F876, PIC16F877

- PIC16F627, PIC16F627A, PIC16F628,

PIC16F628A

- PIC16F648A, PIC16F630, PIC16F676

- PIC18F2550

- Other untested but compatible

with the previous ones.

Configuration for

the proper functioning of the modules

Swtich configuration

of Micro_GT_PIC completed

Scheme

Electric hand to identify each time the position of DIP and

streep cited connectors to enable the various functions or divert the bus from a

position to another card.

For example, the L298 chip that phelot 1

bipolar stepper motor or two motors D.C. (A maximum of 2 per roll)

is enabled by closing the DIP

A.

The DIP

C enables the reading of analog feedback through shunt.

the DIP D allows

hand signals to drive the bridges.

We see the features of the various connectors streep:

SV1 pull

up down buttons S1-S4

SV2 pull

up down buttons S5-S8

SV3 bus

4 lines of command L298

SV4 is

IC connectorSP1 for in-circuit serial programming

(Split with SV9 ovveroICS2 in parallel)

SV5 and

SV6 Pass the clock to the PIC 16F876

SV7 pull

up down buttons S15-S18

SV8 pull

up down buttons S19-S22

SV9

IC is the connectorSP2 for

in-circuit serial programming (Split with SV4 ovveroICS1

in parallel)

SV11/SV12

RS232 direct serial connection supervisor pc control

28 pin serial programming

SV13

and SV14 Pass the clock to the PIC 16F877,

deviation signal

clock / get I / O

SV15

Direct-board analog

SV16 Direct analog or leading to (switch to digital signals to analog)

SV17 Direct port B

SV18 Direct port D

SV19 BCD direct control B0 ÷ B3 led display

SV20 Direct access multiplexer LED display

SV21 Stepper control signal

SV22 Direct control RC 0-3

SV23 Direct control RC 4-7

SV24

RS / RW / EN for LCD or lines RE0, RE1, RE2 of the 16F877

SV25

Contrast adjustment

SV27 Checks port B control the graphic display

SV28 D0 ÷ D7 data to display graphic Glcd

SV29

Direct I / O input connect S15-S22

SV30

Direct I / O input connect S1-S8

We see the functionality of the screw connectors:

X1= Supply of the device, it's good both alternating and

provided between 7 V and 24 V) polarity.

X2= Not present on the card.

X3= Stepper motor power supply phases (eg X3-1 -> +12

Volt While X3-2 -> GND)

X4= Stepper motor phases A and B in sequence

X5= Stepper motor stages C and D in sequence

X6= Motor D.C. (X6-1 induced positive terminal, negative terminal X6-2

induced)

X7= Motor D.C. power supply (X7 DC-DC motor, DC motor mass X7-2)

We see the functionality of the DIP switch:

S9

enable analog feedback from L298

S10

enable L298 (Separately for the two internal H-bridges)

S11 island to door allows entry of analog and digital

S13

onboard output enable (1-port D ,2-C ,3-port port B)

S12 PORT B or tie the island of 16F877, when we open in SV29

available signals from S15 to S22

S14

4 L298 command line enable signal

S24

Enable bridge (If open the pulldown force commands to stop in

both directions)

S25

enable single decimal point on 7

segment display

S26

single line BCD - 7 segment display controller enable

We see the

features of the various jumpers:

JP1

island or spins the clock to OSC1 16F877

JP2

island

or spins the clock OSC2 for 16F877

JP3

If you closed the door power Vss to pin 5 for

16F84A

(Must be up to 4 and 5 SV2).

JP4

If you closed the door power Vdd to pin 14 for

16F84A

(In case of error is not destructive).

JP5

One, connect with flat cable power bipolar 16F877 11-Vdd and

12-Vss or direct RC0, RC1 for 16F876

JP6 flat cable bipolar power LED backlit LCD display

(1-Vdd, 2-Vss)

JP7 backlit graphic display Glcd

JP8 deviation of the clock signal (if closed door signal at PIN 13 - OSC1

for 16F877) is open if RC2-16F876

JP9 deviation of the clock signal (if closed door signal to the PIN 14 - OSC2

for 16F877) is open if RC3-16F876

JP10 Analog sense, is the analog feedback of the two bridges built

sull'L298

NOTE: If we use

16F84A PINs are:

4

MCLR 6 ÷ ÷ 13 RB0 RB7

5

OSC1-OSC2 VSS 16-15

14 VDD

(JP4 close to power PIC16F84 and all the pin to

pin compatible)

SV2 set mode pull-up (jumper right-aligned)

come on P6 MCLR to become 16F84A

Programs

application / demonstration

Will now be presented a series of well-fed programs

programs written in C16 with the dual purpose of being planned and

use the potential of Micro-GT versatile I.D.E.For each

module on the card will be matched with more experience in order

difficulties.

Using seven-segment display module

Exercise 1

View a

count up / count-down controlled by two buttons on the least significant digit

the seven-segment display of the Micro-GT versatile IDE

Solution:

Scheme to

hand can be seen that the least significant digit of the display is enabled by

saturation of the transistor Q4 driven by the line of least significant PORT

B, which is the RB0 pin (No. 33 of the 40-pin PIC). this program

will work for both PIC16F877 PIC16F876 for as long as you make

the appropriate jumper setting relatively dovetailing of the clock

osc1/osc2 their feet.

The number of

display will be coded in BCD lines RB4, RB5, RB6, RB7.

To allow

the transmission of these signals to the device (display) should act on

DIP S26 enabling the channel 8 for the transistor

place the common cathodes of the digit, and the lines representing the nibble 1,2,3,4

BCD.

-

Line 1

RB7 corresponds to the processor and also the bit at the decoder CD4511.

-

Line 2

RB6 corresponds to the processor, enables the bit B.

-

Line 3

RB5 corresponds to the processor, enables the bit C.

-

Line 4

RB4 corresponds to the processor, enable bit D

For safety

disable all channels in the DIP S12 that prevents the arrival of erroneous

signals from the button assembly from S15 to S22.

If we do not want

have a bright echo command disable data channel 3 of the DIP S13.

We set the

according to the logic control buttons pressed = 1, and inputs RA0 R01. To

do this we must dispose of the two jumpers next to Streep that SV2

control buttons to S5 to S8.

Commands

concerned will be S8 -> RA0 And S7 -> RA1

-

If the

16F877 processor chosen is the 20-MHz quartz Q5 is connected to

pins 13 and 14 simply by closing the jumper JP8 and JP9.

-

If the

16F876 processor chosen is the clock signal will be routed to the pin

9 and 10, to do this you must open jumpers JP8 and JP9, and

short SV5 (pins 1 and 2) and SV6 (pins 1 and 2).

E 'can

perform the same exercise using a 18-pin PIC such as the

16F84.

In any case

will be useful to produce an array of certification to be submitted to PORT B as

below.

|

Matrix

generating nibble PORT B |

|

RB0 |

RB1 |

RB2 |

RB3 |

RB4 |

RB5 |

RB6 |

RB7 |

|

1 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|

1 |

0 |

0 |

0 |

0 |

0 |

0 |

1 |

|

1 |

0 |

0 |

0 |

0 |

0 |

1 |

0 |

|

1 |

0 |

0 |

0 |

0 |

0 |

1 |

1 |

|

1 |

0 |

0 |

0 |

0 |

1 |

0 |

0 |

|

1 |

0 |

0 |

0 |

0 |

1 |

0 |

1 |

|

1 |

0 |

0 |

0 |

0 |

1 |

1 |

0 |

|

1 |

0 |

0 |

0 |

0 |

1 |

1 |

1 |

|

1 |

0 |

0 |

0 |

1 |

0 |

0 |

0 |

|

1 |

0 |

0 |

0 |

1 |

0 |

0 |

1 |

To

directly generate the PORT command that has the least significant bit to the right

we must reverse the symmetrical matrix.

|

Matrix

generating nibble PORT B Direct |

|

RB0 |

RB1 |

RB2 |

RB3 |

RB4 |

RB5 |

RB6 |

RB7 |

|

0 |

0 |

0 |

0 |

0 |

0 |

0 |

1 |

|

1 |

0 |

0 |

0 |

0 |

0 |

0 |

1 |

|

0 |

1 |

0 |

0 |

0 |

0 |

0 |

1 |

|

1 |

1 |

0 |

0 |

0 |

0 |

0 |

1 |

|

0 |

0 |

1 |

0 |

0 |

0 |

0 |

1 |

|

1 |

0 |

1 |

0 |

0 |

0 |

0 |

1 |

|

0 |

1 |

1 |

0 |

0 |

0 |

0 |

1 |

|

1 |

1 |

1 |

0 |

0 |

0 |

0 |

1 |

|

0 |

0 |

0 |

1 |

0 |

0 |

0 |

1 |

|

1 |

0 |

0 |

1 |

0 |

0 |

0 |

1 |

We develop the

two software modules so as to maintain a more professional style of

programming.

In a form

setting.h preset called the internal registers of the microprocessor, while

numeratore_up_Down.c insert a module called the main function "main",

even agreed to run two modules of different settings that will be

included as needed depending on the controller that we will

choose.

//---------- Form

setting16F84.h---------------

# Define UP

RA0 / / a button that launches the count up

# Define DOWN

RA1 / / Button 2 launches the count back

void

settings (void) {

TRISA = 0b00011;

TRISB = 0b00000000;

PORTB = 0;

}

//--------- Form setting16F877-876.h

# Define UP

RA0 / / a button that launches the count up

# Define DOWN

RA1 / / Button 2 launches the count back

void

settings (void) {

TRISA = 0b00011;

TRISB = 0b00000000;

Trisch = 0;

TRISD = 0;

TRIS = 0;

}

//--------------- Module

numeratore_up_Down.c------------------

# Define

XTAL_FREQ 4MHZ / / header is used in delay, Place a comment

this line if using PIC16F876 or 877

# Define

XTAL_FREQ 20MHZ/ / Put in this comment

line if we use PIC16F84

# Include <pic.h>

/ / Make the compiler know the names of the internal registers of the PIC

# Include <delay.h>

/ / Function prototype delay

# Include <delay.c>

/ * __CONFIG (HS

WDTDIS PWRTEN & & & Unprotect) * /

/ / Set

cast for the 16F84

__CONFIG (HS &

WDTDIS PWRTEN & & & BORDIS LVPDIS DUNPROT & & & WRTEN DEBUGDIS & Unprotect);

/ / Set

merged if the 16F876 or 16F877

# Include "setting.h"

/ / Setting form of external registers

void main (void) {

settings ();

while (1) {

if (UP == 1) {

DelayMs (100);

if (UP == 1) {

PORTB = 0b00000001;

DelayMs (255);

DelayMs (255);

DelayMs (255);

PORTB = 0b10000001;

DelayMs (255);

DelayMs (255);

DelayMs (255);

PORTB = 0b01000001;

DelayMs (255);

DelayMs (255);

DelayMs (255);

PORTB = 0b11000001;

DelayMs (255);

DelayMs (255);

DelayMs (255);

PORTB = 0b00100001;

DelayMs (255);

DelayMs (255);

DelayMs (255);

PORTB = 0b10100001;

DelayMs (255);

DelayMs (255);

DelayMs (255);

PORTB = 0b01100001;

DelayMs (255);

DelayMs (255);

DelayMs (255);

PORTB = 0b10000111;

DelayMs (255);

DelayMs (255);

DelayMs (255);

PORTB = 0b00010001;

DelayMs (255);

DelayMs (255);

DelayMs (255);

PORTB = 0b10010001;

DelayMs (255);

DelayMs (255);

DelayMs (255);

}

if ((up == 0) & & (DOWN == 0)) {

PORTB = 0b00000000;

/ / Clear all outputs including RB7 -> Q4 which turns off the display

}

}

if (DOWN == 1) {

DelayMs (100);

if (DOWN == 1) {

PORTB = 0b10010001;

DelayMs (255);

DelayMs (255);

DelayMs (255);

PORTB = 0b00010001;

DelayMs (255);

DelayMs (255);

DelayMs (255);

PORTB = 0b10000111;

DelayMs (255);

DelayMs (255);

DelayMs (255);

PORTB = 0b01100001;

DelayMs (255);

DelayMs (255);

DelayMs (255);

PORTB = 0b10100001;

DelayMs (255);

DelayMs (255);

DelayMs (255);

PORTB = 0b00100001;

DelayMs (255);

DelayMs (255);

DelayMs (255);

PORTB = 0b11000001;

DelayMs (255);

DelayMs (255);

DelayMs (255);

PORTB = 0b01000001;

DelayMs (255);

DelayMs (255);

DelayMs (255);

PORTB = 0b10000001;

DelayMs (255);

DelayMs (255);

DelayMs (255);

PORTB = 0b00000001;

DelayMs (255);

DelayMs (255);

DelayMs (255);

}

if

((UP == 0) & & (DOWN == 0)) {PORTB = 0b00000000;} / / Off the display

}

/ / End of loop

} / / End of

main program

Using

Module L298 for stepper motor

The

L298 default form is disconnected from the rest of the circuit so as not to

affect the operation during the use of other modules. Also for

default input of each bridge chip is brought to logic zero

thanks to the on-baord of their respective pulldown resistors.

for

module operation make the following settings

-

enable the two bridges inside H acting on S10 (every one of these channels enables

a bridge inside)

-

link

with 4-way flat cable to the desired port SV3 (SV17 Board - PORT B, lines

Pin 0,1,2,3 or 33,34,35,36)

-

S13 enabling channel 3 (with flat cable which suggested above) will see the echo

step-matrix LED on RB0 to RB3

-

Connect with flat cable with two conductors in SV16 JP10 to read the

extra current analogue signal (enable S9)

-

connect the motor to the screw terminals bipolar X4-1 -> A, X4-2 -> B, X5-1 -> C,

X5-2 -> D

-

Feed the engine with its own specific voltage at the terminals X3-1

Positive, and X3-2 mass (the power is independent while the positive

mass is common).

Exercise

Acting

a button (initially bistable) the stepper motor is put in

clockwise rotation (clockwise or CW). Acting on a second button, the motor

it rotates counter-clockwise (anti clock wise ACW). Lends

attention to the commands antagonists, or the engine does not accept the command if it is

yet the opposite feature. It uses the Micro-GT versatile I.D.E.

After making the necessary connections and hardware settings.

Solution:

The settings

Hardware should be performed, plans in hand, according to the list

bulleted above. In doing so we can send four signals matrix

full step (full step) to bits of PORT B.

/ / TOF

led by Save As Micro-GT stepper1.c

/****************************************

* Micro-GT Versatile IDE

*

*

Form L298

*

* Drive stepper motor *

* Professor.

Marco Gottardo *

*

April 2010

*

****************************************/

/******** List of duties *********

CW RA0

ACW RA1

mot_A RB0

mot_B RB1

mot_C RB2

mot_D RB3

***************************************/

# Include <pic.h>

# Include <delay.h>

# Include "setting16F877.h"

Full_CW void () {

while (ruotaCW == 1) / / double equals to compare

{/ / Implement the full array of step 10,6,5,9

PORTB = 10;

DelayMs (200);

PORTB = 6;

DelayMs (200);

PORTB = 5;

DelayMs (200);

PORTB = 9;

DelayMs (200);

}

}

Full_ACW void () {

while (ruotaACW == 1) / / double equals to compare

{/ / Implement the array of step

Full reverse 9,5,6,10

PORTB = 9;

DelayMs (200);

PORTB = 5;

DelayMs (200);

PORTB = 6;

DelayMs (200);

PORTB = 10;

DelayMs (200);

}

}

void main (void) {

settings ();

while (1) {

if (CW == 1) {

DelayMs (100) / / debounce

if (CW == 1) {

Full_CW ();

}

}

if (ACW == 1) {

DelayMs (100) / / debounce

if (CW == 1) {

Full_ACW ();

}

}

}

}

/ / End of

main module that contains the main function

Settings

Tristan and logs the initialization of variables of I / O, as well as

definitions of new names for the same are implemented in a form

external program. the file will be saved and type header with the name

setting16F877.h

Within

this header file implement the function settings () fixing the

buffer in the direction of pin I / O for the entire program execution.

/ / *************** Early

form setting16F877.h ***************

CW # define RA0 / / Button 1, which

motor rotates them forward

# Define ACW RA1 / / Button 2 engine that rotates them back

/ / Draws up the definitions of each stage

/ / I can not use them but they are compatible to future changes

# Define mot_A RB0 / / Phase A of the stepper motor

# Define mot_B RB0 / / Phase B of the stepper motor

# Define mot_C RB0 / / C phase stepper motor

# Define mot_D RB0 / / D phase stepper motor

void settings (void) {

TRISA = 0b00011;

TRISB = 0b00000000;

Trisch = 0;

TRISD = 0;

TRIS = 0;

}

/ /

end of the form setting16F877.h

image

see the following development environment MPLAB Microchip home where

you compiled in ANSI C program.

Cow can we

see the compilation is successful. If this does not happen the problem

is resolved by placing the locations to find libraries delay.h delay.c

that should be moved to the include directory of the compiler. Proceed elina

files from project and replace after it is returned in the directory

just indicated. The external module instead must be in the same folder

funzone module containing the main (void).

In summary:

-

create a

folder inside documents and nominiamola Micro-GT stepper1

-

we create two

file with notepad

stepper1.c and

setting16F877.h (Or Scarichiamoli and copy it in there using these

two links).

-

make sure

that libraries delay.h and

delay.c be included on

folder includes the compiler.

-

we follow the

wizard of the project using project wizard (appointed

project Micro_GT_stepper1)

-

compile

acting on the red and black squares on the command bar of MPLAB.

-

if everything is

place the system responds with **** Build Successful! *** as shown above,

then we can go to the project folder to find the file

Micro_GT stepper1.hex

Finally, to revert to the memory of the PIC. This maneuver is writing

note on the web with the word "flasc_assare" PIC.

you can download

the entire project from this link packaged with the appropriate button MPLAB, but

some paths may need to be adjusted in accordance with

advancement of the compiler or version upgrades or software

development.

Download the complete project for MPLAB

NOTE:

This work (diagrams and board layout Micro-GT), is awarded to the terms

License

Creative Commons Attribution-ShareAlike 3.0 Italy

|